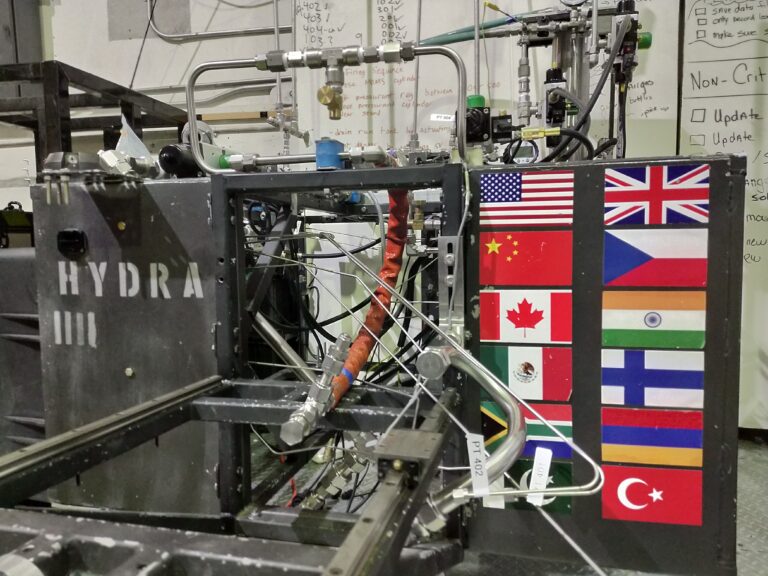

LPL’s current capabilities include engine development, feed system development, test operations and academic studies focusing on liquid propulsion technologies. Although a priority of our lab is to operate at a level close to industry standards, publishing research papers and partaking in academic conferences have added great value for the lab.

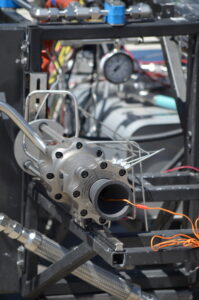

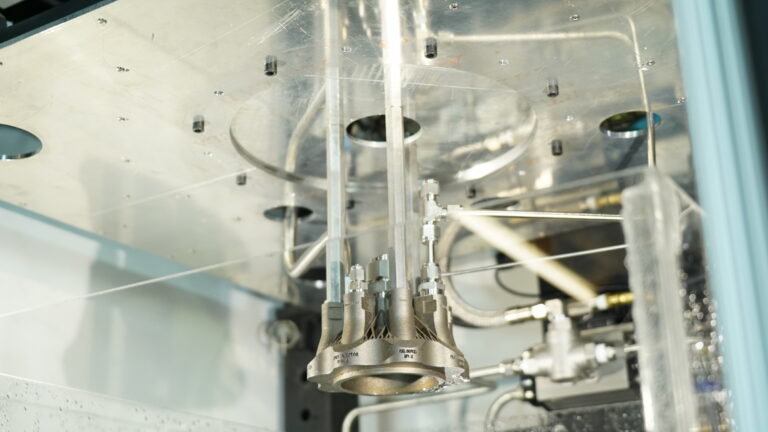

To date, LPL has designed and manufactured five engines; production of three of them were accomplished via additive manufacturing with the help of USC’s Center of Advanced Manufacturing and several companies. During engine development, our team strictly followed industry standards for each phase of the development from beginning to end. Designing, manufacturing, testing and analyzing data at such a level ensures the life cycles of our engines; and, provide a professional learning experience, independent from the end results.

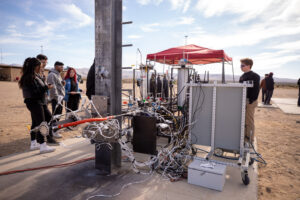

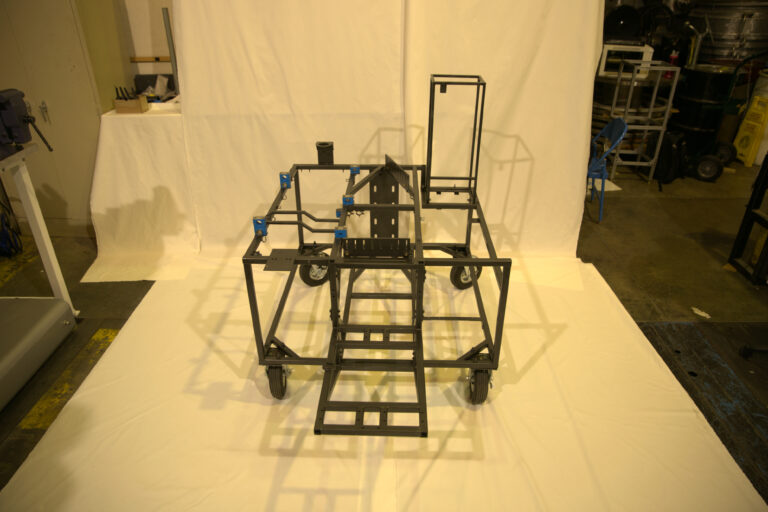

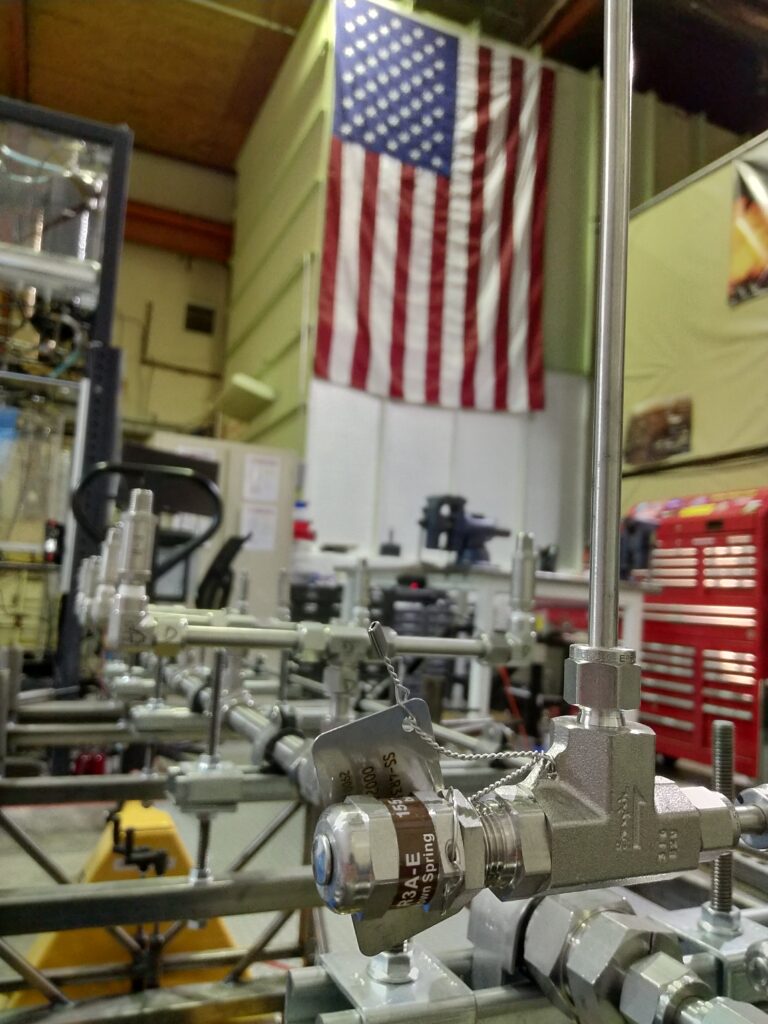

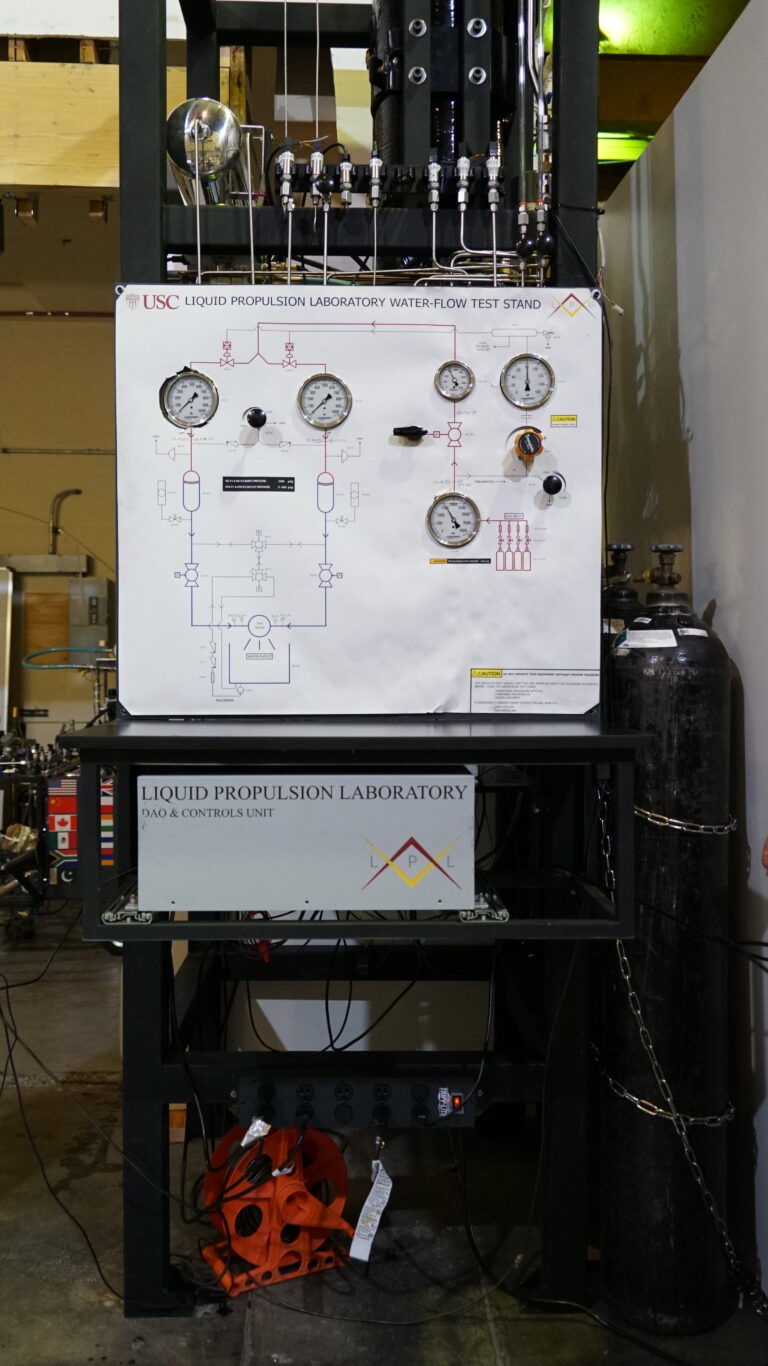

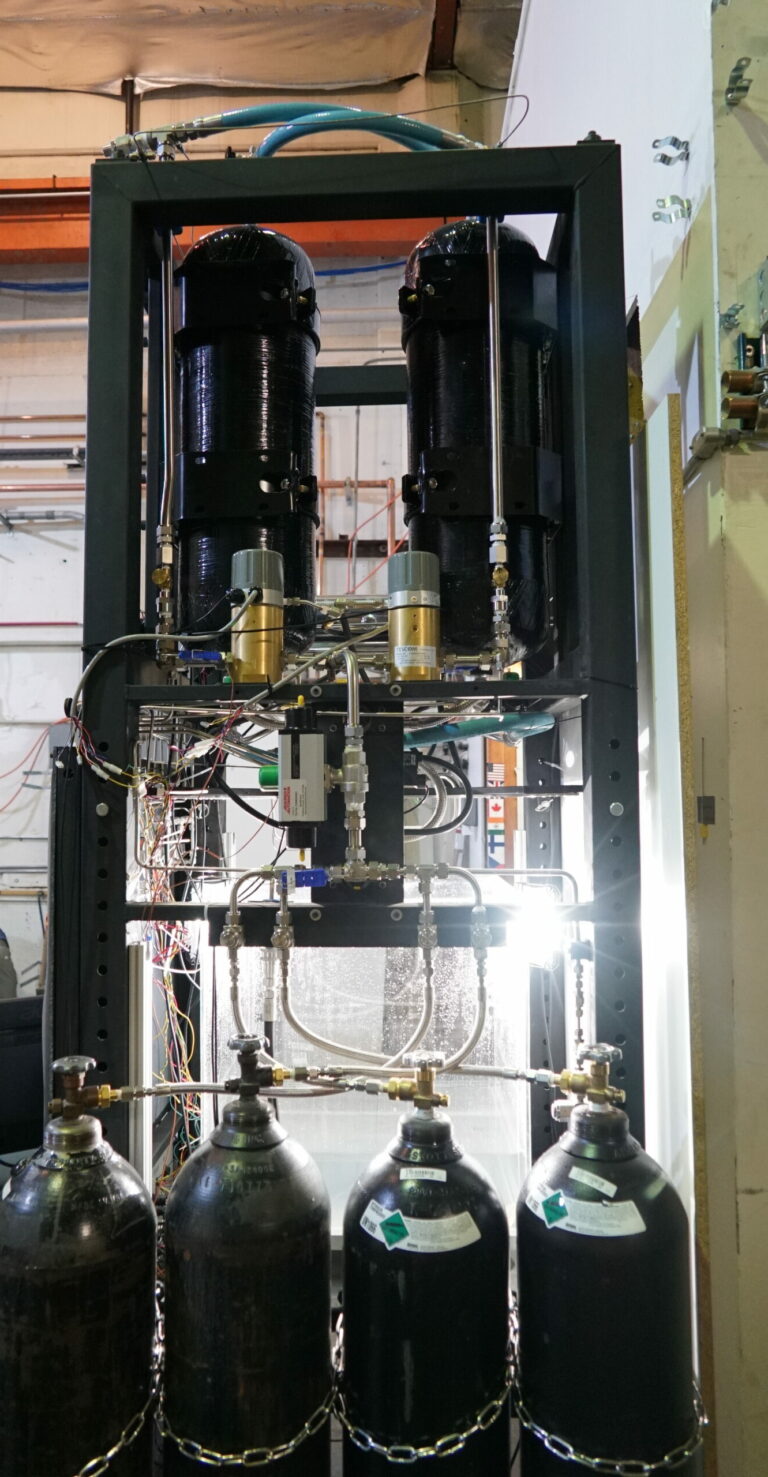

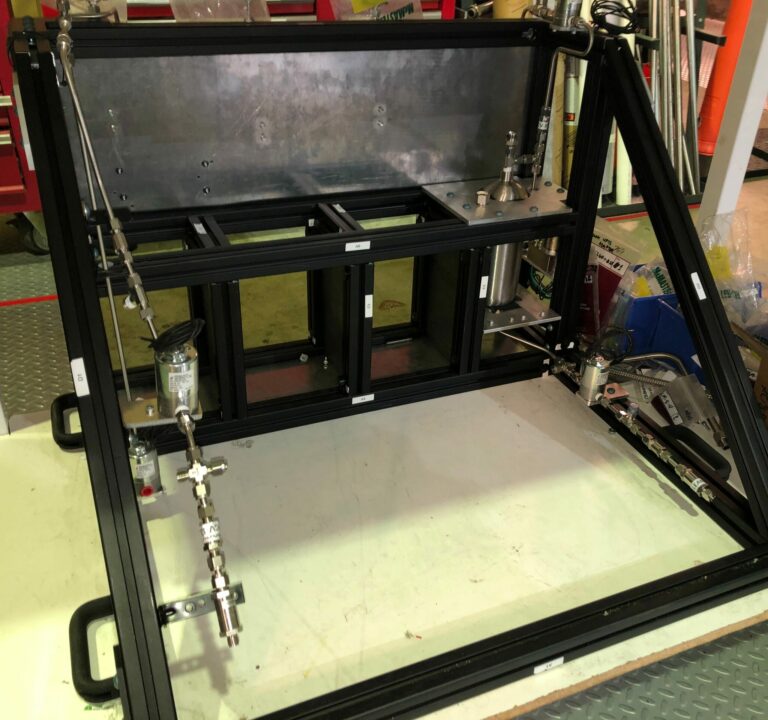

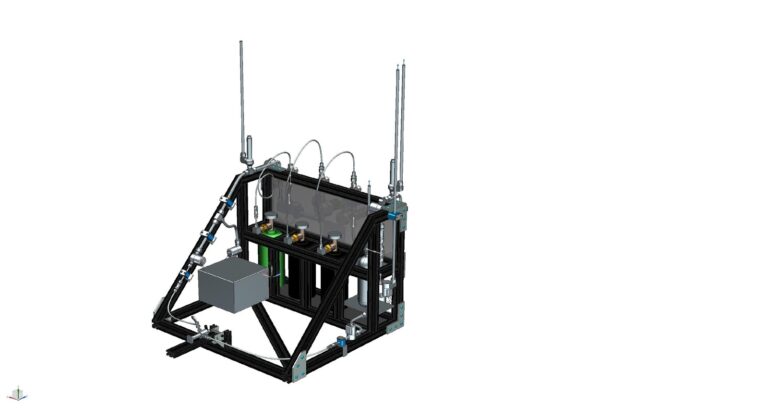

LPL has developed over 3 unique feed systems for a range different uses: an engine test stand that powers gaseous oxygen/kerosene engines with thrust levels up to 1000 lbf, a vertical test unit that precisely characterizes flow orifices such as injectors, and a portable feed system used to prototype torch igniters. LPL’s feed systems are developed, operated and tested entirely in-house by our members and are continuously improved. Furthermore, the lab is always developing new test stands to expand our capabilities.