Feed System Development

LPL has developed over 3 unique feed systems for a range different uses: an engine test stand that powers gaseous oxygen/kerosene engines with thrust levels up to 1000 lbf, a vertical test unit that precisely characterizes flow orifices such as injectors, and a portable feed system used to prototype torch igniters. LPL’s feed systems are developed, operated and tested entirely in-house by our members and are continuously improved. Furthermore, we always strive to develop new test stands in order to utilize our skills and expand our capabilities. We expect to begin the design of a cryogenic rated feed system this year.

Atlas, a bi-propellant pressure fed feed system geared towards providing LPL members with hands-on exposure to cryogenic fluid handling and operations, was completed in December 2023. Designed initially for the hot firing of the Balerion engine, Atlas boasts the capacity to support engines with specifications up to three times larger than Balerion. It is capable of safely static firing cryogenic propellant engines with thrusts greater than 10kN and up to 13kg/s mass flow rates, and has been designed to incorporate as many refurbished valves, fittings, and components from Hydra as possible. Atlas expands lpl’s testing capabilities with improved flow rates and burn times, and is set to serve as the lab’s primary testing infrastructure for years to come

Atlas, a bi-propellant pressure fed feed system geared towards providing LPL members with hands-on exposure to cryogenic fluid handling and operations, was completed in December 2023. Designed initially for the hot firing of the Balerion engine, Atlas boasts the capacity to support engines with specifications up to three times larger than Balerion. It is capable of safely static firing cryogenic propellant engines with thrusts greater than 10kN and up to 13kg/s mass flow rates, and has been designed to incorporate as many refurbished valves, fittings, and components from Hydra as possible. Atlas expands lpl’s testing capabilities with improved flow rates and burn times, and is set to serve as the lab’s primary testing infrastructure for years to come

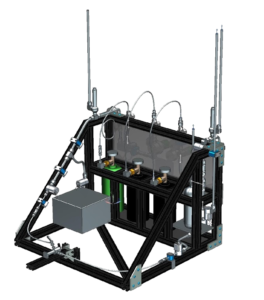

WFTS aims to improve LPL’s ability to cold-flowing liquid rocket engine and feed system components on campus. Our goal for WFTS is to be able to determine the flow and discharge coefficients of test articles with an accuracy of better than 1 percent. The system will also be used for examining injector spray formation, conducting atomization research, testing cooling systems, testing throttle valve functionality, and as a learning tool for new lab members.

Specifications:

- Two main water lines to simulate fuel and oxidizer flow

- Water flow at mass flow rates of up to 5 kg/s

- Operation at pressures up to 900 psig

- Automated data acquisition

- Pressure control through an electro-pneumatic regulator

- Emergency pressure venting

- Adjustable mounting platform for different size of test article with maximum diameter of 10”

- Minimum of three screw-in rods must be connected to the test article and in turn to the platform with a desired size

- Up to three pressure transducers can be connected to the test article

Hodor was designed for a liquid oxidizer and liquid fuel combination. It was successfully characterized during our Mike’s Fury hot fire test in Spring 2023.

Specifications:

- Mobile pressure regulated test stand designed for a liquid oxidizer, a liquid fuel, and a pressurized inert gas used for the fuel

- Can provide oxidizer line pressures up to 745 psia and fuel line pressures up to 1020 psia

- Oxidizer and fuel line purges provided by N2 purge lines

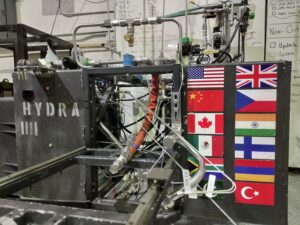

Hydra, now retired, was designed to test gaseous oxidizer and liquid fuel engines. Hydra could operate engines providing a thrust up to 1000 lbf and was capable of supplying up to one gallon of fuel per firing. A modification to Hydra was the Mobile Oxygen Manifold System (MOMS). This system consists of 8 pressurized oxygen tanks and 1 pressurized nitrogen tank. Each high-pressure tank is securely fastened to MOMS at 2 different points to prevent any single point failures. The oxygen tanks provided Hydra and the engine with oxidizer and the nitrogen tank is used for purging the lines pre- and post-firing. Hydra was designed with several key aspects in mind: portability, modification, versatility, and safety. Hydra was a critical milestone for LPL’s future capabilities and will be used as a platform to test and modify future engine and feed systems.

Specifications:

- Mobile pressure regulated test stand designed for a gaseous oxidizer, a liquid fuel, and a pressurized inert gas used for the fuel

- Capable of testing engines with thrust up to 1000 lbf

- Can provide oxidizer line pressures up to 1500 psig and fuel line pressures up to 1800 psig

- Oxidizer and fuel line purges provided by N2 purge lines

- Data collection performed by National Instruments modules with connection to 9 pressure sensors and 6 temperature sensors on the test stand

Prometheus is a miniature test stand, which operates as pressure fed and regulated system, designed to test torch igniters with a maximum bottle pressure of 2000 psi and a maximum operating pressure of 1000 psi. Prometheus is a bi-propellant feed system designed to flow GOx and GH2 into mounted torch ignition systems. The use of this system will allow us to transfer away from pyro igniters and move towards more reliable torch igniters. Pyro igniters do not allow for rapid engine restarts as the solid fuel charge needs to be replaced between firings, requiring any feed system used to be put into a completely safe state. Prometheus will improve LPL’s testing infrastructure with its portable and modular design, allowing for ease of use and ease of modifications in the future.

Specifications:

- GOx / Hydrogen feed system

- N2 is used as a pressurant as well as for the system’s purge

- The system is operated using solenoid valves at a standard operating pressure of 1500 psi

- The dimension of the system are 33 “ x 38” x 29”